+ Sturm

+ Sturm

"Our engineers and customers are now using the new system and the response has been overwhelmingly positive. We are delighted with the result."

— Jason Sim, Project Engineer

Market leading efficiency

Smardt are a leading manufacturer of high-efficiency chiller systems used to cool hospitals, universities, large office buildings, hotels and data centres. They have an install base of well over 5000 systems worldwide and production facilities in Stuttgart, Melbourne, Plattsburgh, Guangzhou and Montreal. Smardt lead the market in energy efficiency and low lifetime operating costs due to their unique oil-free centrifugal technology.

"Cooling is a major cost in operating a large building, so our customers are highly motivated to reduce these costs" explained Jason Sim, Project Engineer.

Our competitors had an offering and we didn't

"Having a cloud monitoring product had always been our goal. We looked at off-the-shelf products, but these were not economical at our scale, so we knew we had to build our own. The next problem was that no-one in our organisation had the experience to build this cloud. We work with PLCs, process control logic and a little bit of coding in Java and Python. I've been in the HVAC industry for more than 10 years, but this was my first time managing a software project. We needed a great result and my reputation was on the line."

"We had a good idea of how the product should work, but I was unsure about how the technology would fit together. Ben and the team worked closely with us to tackle the most challenging aspects first and to demonstrate that the approach would work."

— Jason Sim, Project Engineer

Building the Smardt cloud

Sturm worked with Smardt to break down their goals into a two-year road-map and a series of fixed-timeline projects.

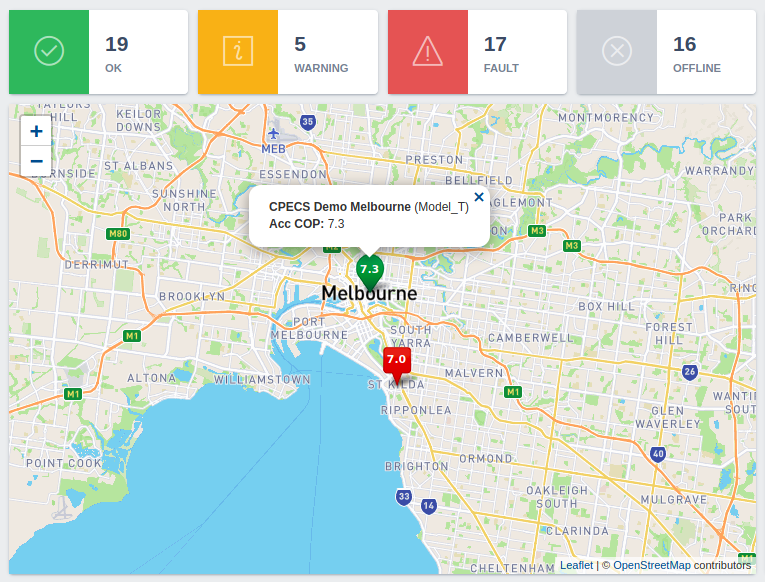

In the initial proof-of-concept phase Sturm developed a system to capture basic health and performance statistics from connected chillers and display this information on a live-updated map dashboard, working with Smardt engineers to integrate with the on-site chiller controllers. This allowed Smardt customers and engineers to log into their personalised dashboard and get a quick overview of the status of their chillers.

"Ben and the team completed the project two weeks ahead of schedule," recalls Sim. "We're delighted with the result."

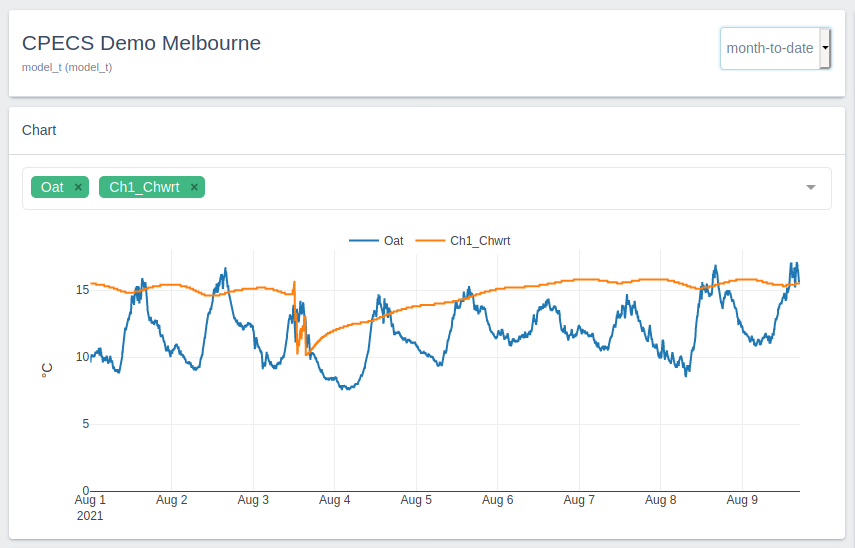

In the second phase, a long-term history facility was added to collect more than five hundred different readings from each connected chiller system every five minutes and store them for up to ten years. Trend charts data can be viewed and data can be exported through the online dashboard, allowing customers to dive deeply into the long-term performance of their chillers.

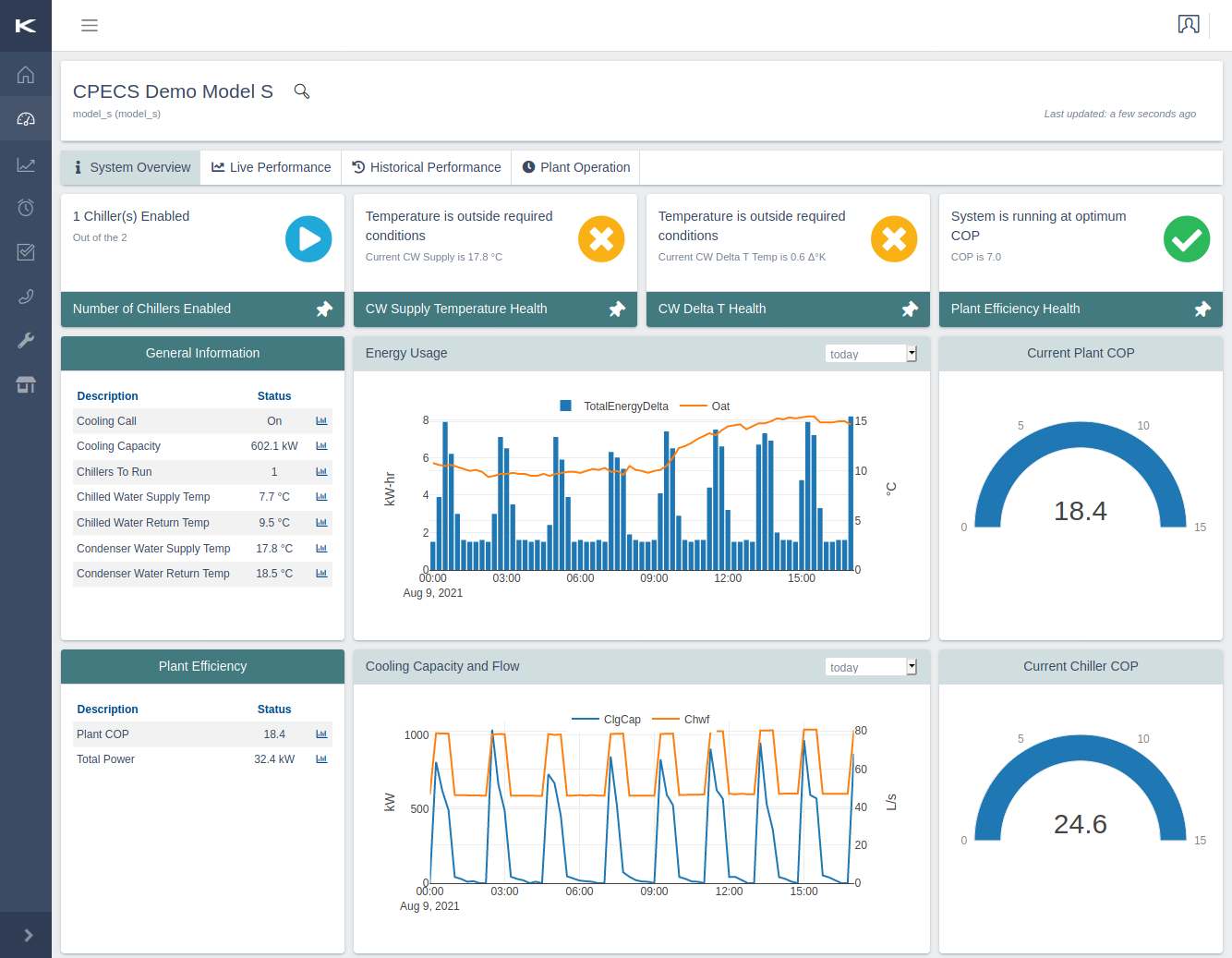

The third phase added a real-time data dashboard to give building managers and engineers full details of how their chiller systems are performing at that moment. This information was previously only available by onerously dialling in to each chiller system individually.

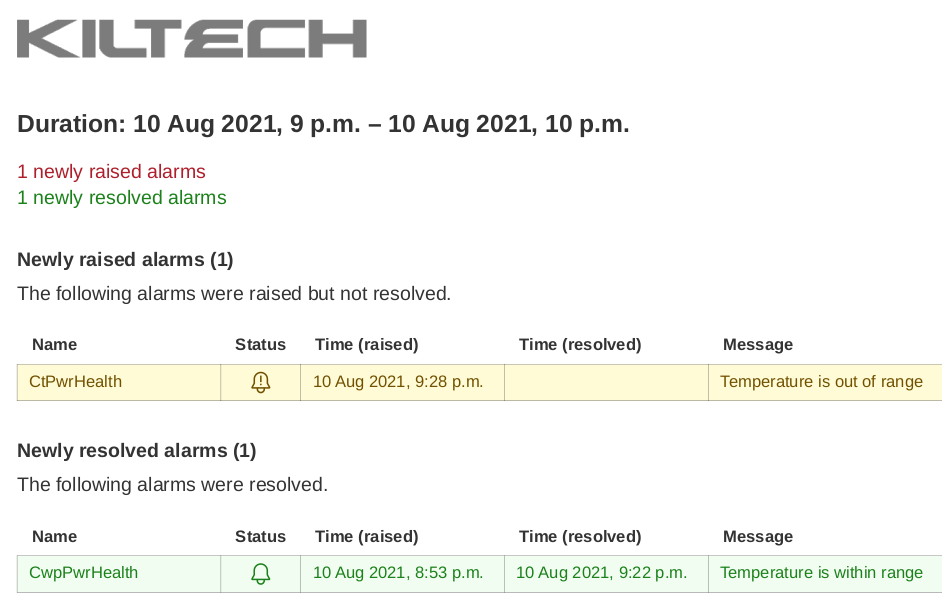

An alarm system was added in the fourth phase to collate all the alerts raised by each chiller system into attractive reports and periodically email these to building managers. This helps building managers deal with problems effectively, rather than missing the major issues because they're swamped with insignificant notifications.

"Our industry is fairly conservative, so we knew we had to build our cloud product in a staged approach to demonstrate value to our customers and get financial support from top management. That can be frustrating, but Sturm understood our needs. We also like things to be simple and practical and Sturm have been very compatible in that respect."

"Our engineers and customers are now using the new system and the response has been overwhelmingly positive. We are delighted with the result."